REFRIGERATOR:

A dilution refrigerator is a device that can achieve and maintain

temperatures near 7 mK.

It can be divided into four main sections: 4He pot, still,

heat exchangers and mixing chamber. A mixture of 4He

and 3He gas is condensed into the fridge at the 4He

pot, which is cooled to 1 K by evaporative cooling of 4He.

The liquid helium mixture is pumped at the still which further cools

the mixture to around 0.3 K, by evaporative cooling of 3He.

Below 0.8 K the mixture of 4He and 3He phase

separates into two phases: one is pure 3He and the other

is 4He with a small quantity of 3He, the so-called

dilute phase. The boundary between these two phases sits in the

mixing chamber. As the still is pumped, differences in vapor pressure

between the two isotopes leads to 3He being primarily

removed from the dilute phase in the still. It is then energetically

favorable for 3He in the pure side to move across the

phase boundary to replenish the dilute side. This movement of 3He

from the concentrated phase into the dilute phase is analogous to

evaporation and has associated with it a latent heat. The 3He

that is pumped off at the still is returned to the pure side of

the mixing chamber by liquification at the 4He pot and

is precooled through a series of heat exchangers in order to continue

the cooling process.

SAMPLE

REGION: CALORIMETER

Thermodynamic properties of superfluid 3He, such as specific

heat, are measured in this experimental sample region. Specific

heat measurement requires low and controlled heat capacity for materials

other than the substance of interest, 3He in this case.

Therefore, a superconducting cadmium heat switch is used to isolate

the sample cell from the nulcear stage for the measurements. Also,

low heat leak into 3He is crucial, and disconnecting

the sample cell from the nuclear stage enables us to reduce the

heat leak into 3He to as low as 80 pW. Once the sample

is cooled to sub-mK, a standard adiabatic heat pulse technique is

used to measure the heat capacity.

ADIABATIC

NUCLEAR DEMAGNETIZATION:

In the nuclear stage a paramagnetic material, either Hitachi copper

or praseodymium-nickel-5, is placed in an external magnetic field

of ~8 T. With the field in place the nuclear spins in the paramagnetic

material align parallel to the field. The field is then slowly (adiabatically)

lowered to zero and the system of nuclear spins disorder from the

low entropy (ordered) state into a configuration of higher entropy.

This proccess absorbs heat and cools the 3He down to

~500 µK.

NMR

SAMPLE REGION:

Using nuclear magnetic resonance (NMR) the spin state and spin dynamics

of superfluid phases of 3He are studied in this sample

region. This is, in fact, how the superfluid phases of 3He

were discovered and identified at Cornell University in 1972. This

discovery led to the Nobel Prize in Physics in 1996. Here at Northwestern

we have studied the magnetization of superfluid 3He-B

and NMR of superfluid 3He in aerogel.

|

|

| |

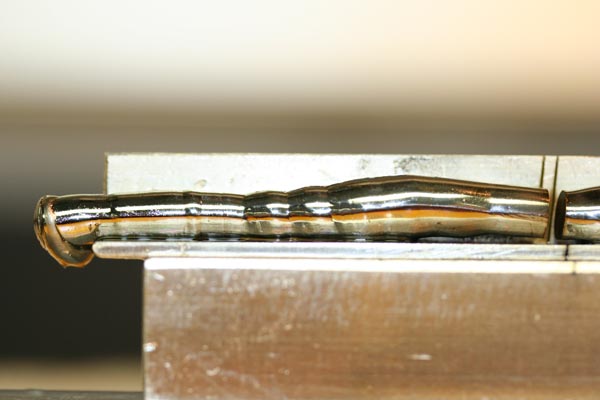

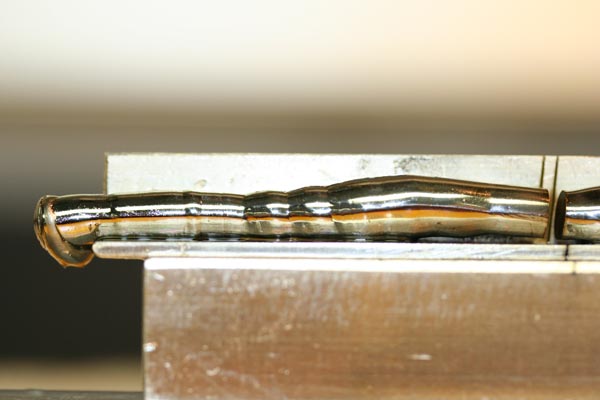

UPt3 Zone Refining and the Final Product

|

|

| |

|

|

| |

|

| UPt3 Wafers | |

The Crystal Growth and Characterization Laboratory is dedicated to producing high-quality, single crystals of the unconventional superconductor UPt3.

In addition to our own experiments, we have supplied samples to collaborators around the world for study using Josephson interference, low temperature specific heat, NMR,

high energy X-ray diffraction, magnetic penetration depth, and magnetic susceptibility among many other techniques.

|  |

| Dilution Refrigerator and Sample Suspended

Above PSI Facility | |

At present, our own experimental focus is on small angle neutron scattering (SANS) from the Abrikosov vortex lattice.

Our SANS experiments, currently based at the Paul-Scherrer Institute in Villigen, Switzerland,

aim to test predictions of chirality and unusual vortex structures in the superconducting B and C phases.

The small interaction between the neutron magnetic moment and the magnetic flux quanta that form a lattice in the

superconducting mixed state provide an excellent tool for investigating the nature of the superconducting order in bulk single crystals.

The large, high quality crystals we grow at Northwestern University have shown minimal flux pinning, making them ideal for SANS experiments.

|

| Annealing Furnace |

Other experiments being considered in the near term include studying the thermal conductivity at low temperatures

in the clean limit using a unique wafer geometry, measuring the magnetoresistance in the normal state down to 7 mK

to determine the magnetic nature of the specific heat anomaly, as well as continued collaborations for neutron scattering,

Josephson tunneling, DC low-field magnetic susceptibility, and NMR.

And like all good scientists, we're continually interested in new and exciting ideas for experiments and collaborations.

|

| Arc Melter | |

To make a crystal of UPt3, we begin by electromigration purifying uranium.

The resulting high-purity uranium is then melted with platinum at proper stoichiometry in our arc melter under a high purity argon atmosphere.

This produces polycrystalline rods, which are then loaded into the zone refiner. Under ultra high vacuum (UHV),

|

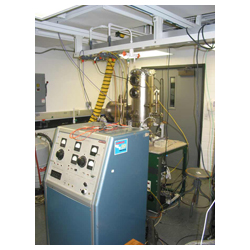

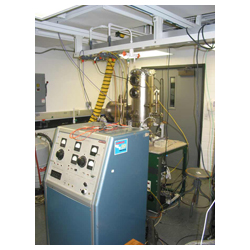

| Zone Refiner |

we bombard the sample with 8 kV electrons to produce a molten section in the rod, or molten zone.

This molten zone is then translated up the length of the polycrystalline material.

What is left behind after the molten zone freezes is hopefully a single crystal with randomly oriented crystallographic axes.

We then cut samples in convenient experimental geometries from the crystal by electro-discharge machining (EDM),

after identifying the symmetry axes by Laue X-ray diffraction. The samples are then etched, some are polished, and all are annealed.

Proper annealing at low temperatures in ultra high vacuum is crucial to producing the highest quality samples.

Our meticulous methodology has paid off, producing some of the finest UPt3 crystals in the world.

|

|

| |

|

Uranium Electro-Migration

Purifier

|

EDM

|

Zone Refiner Innards

|

|

| |

|

Denton High Voltage Source

(Zone Refiner in Background)

|

Sample Being Prepared

in Holder for Neutron Scattering

|

| |

Home

| Aerogel | 3He Calculator

| People | Facilities

| Publicati

|